Latest

News

Topics

- About Maple (100)

- Car Parks (90)

- Office and Retail (47)

- Government (39)

- Rainscreen (36)

- Louvres (30)

- Education (24)

- Residential (24)

- Brise Soleil (22)

- Health (20)

- HSEQ (18)

- Commercial Blinds (16)

- Sustainability (15)

- Data centres (10)

- Pre-Construction services (10)

- Architectural facade (7)

- North West (2)

Our team carried out onsite face fit testing for dusk masks to protect members from silica dust.

Health and safety has always been a vital consideration in all that we do at Maple and we have a dedicated HSEQ department that monitors our processes to ensure we’re following industry standard procedures. As a testament to our team, it's been 1420 days since our last LTI (lost time incident).

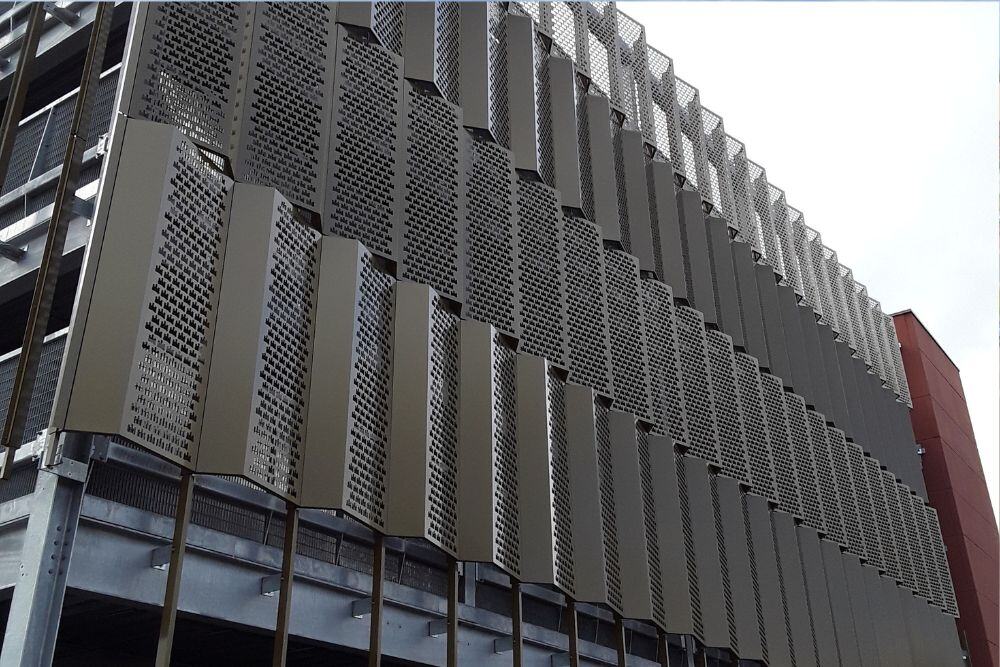

Most recently, we have been showing our commitment to health and safety onsite of our façade installation at Newcastle-Under-Lyme. In early 2024, we won the contract to install a bespoke perforated panel and expanded mesh façade for a new multi-storey car park in the West Midlands. The panels feature unique castle-shaped perforations as a nod to the town’s heritage and coincide with the car park’s name: ‘Castle Car Park’.

To attach the façade panels onto the concrete structure, installers first need to drill into the concrete which releases harmful silicon dust into the air. When inhaled over time, silicon can pose significant health risks such as silicosis, lung cancer and many other respiratory problems. To prevent these issues, our site team have been carrying out face-fit testing for dusk masks so they can drill into concrete safely without the fear of breathing in silica dust.

As well as adhering to proper health and safety measures, our team has been making excellent progress in collaboration with Morgan Sindall Construction and the project is nearing completion.